Full Analysis of Extrusion Coating Lamination Machine Maintenance

Datetime: 1/10/2025 4:28:00 PM Visit: 1878

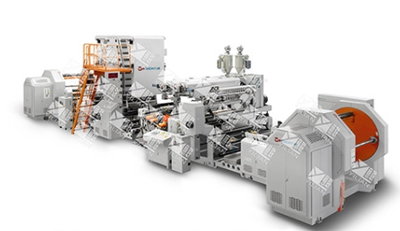

The Extrusion Coating Lamination Machine plays a crucial role in numerous industrial production fields. To ensure its stable operation, proper maintenance is of utmost importance.

I. Preparation before Maintenance

1.Safety Protection:Maintenance personnel must wear protective gloves, goggles, and other equipment to avoid injury during the operation.

2.Tool Preparation:Prepare common maintenance tools such as wrenches, screwdrivers, pliers, etc., and also ready professional testing instruments such as infrared thermometers and electrical multimeters.

3.Shutdown and Power Off:Strictly follow the operating procedures to turn off the equipment and cut off the power supply to ensure the safety of the maintenance process.

II. Common Malfunctions and Maintenance Steps

(I) Unstable Extrusion Quantity

a.Check the Raw Material Supply System:Check if there is enough raw material in the hopper and whether the raw material conveying pipeline is blocked. If there is a blockage, the pipeline needs to be disassembled for cleaning.

b.Check the Screw:Screw wear may lead to unstable extrusion quantity. Measure the outer diameter of the screw with professional tools and compare it with the standard value. If the wear is severe, the screw needs to be replaced.

c.Check the Extruder Temperature Control System:Use an infrared thermometer to detect whether the temperature of each heating zone is normal. If the temperature is abnormal, check whether the heating element is damaged and whether the thermocouple is working properly. If the heating element is damaged, it needs to be replaced in a timely manner.

(II) Poor Lamination Effect

Check the Coating Roll:Observe whether there is wear, scratches, or foreign matter attached to the surface of the coating roll. If so, the coating roll needs to be repaired or cleaned. Slightly scratched areas can be gently sanded with sandpaper, and for foreign matter, use a special cleaning agent to wipe.

Adjust the Lamination Pressure:Insufficient lamination pressure may result in a poor lamination effect. Gradually increase the pressure through the pressure adjustment device and observe the lamination effect until the optimal state is achieved.

Check the Adhesive Supply System:Check if there is enough adhesive in the adhesive storage tank and whether there is any leakage in the adhesive conveying pipeline. If there is a leakage, repair the leakage point and replenish the adhesive.

III. Common Q&A

(I) Q: How to determine if the heating element of the extruder is damaged?

A: You can use an electrical multimeter to measure the resistance value of the heating element. If the resistance value deviates significantly from the standard value, it indicates that the heating element may be damaged. Additionally, you can also observe whether the heating element has a normal heating phenomenon such as redness when energized. If not, it may be damaged.

(II) Q: What needs to be done after the coating roll is repaired?

A: After the coating roll is repaired, it is necessary to conduct a dynamic balance test. If the dynamic balance does not meet the requirements, vibration will occur during the operation of the equipment, affecting the coating and lamination effects. A professional dynamic balance testing machine can be used for testing and adjustment.

(III) Q: Does the equipment require special maintenance when it is not used for a long time?

A: When the equipment is not used for a long time, the remaining raw materials in the hopper should be cleaned up to prevent the raw materials from caking. At the same time, replenish lubrication at each lubrication point to prevent the equipment from rusting. In addition, the equipment can be powered on and idled at regular intervals to check whether the equipment is normal.

Through the above maintenance instructions and Q&A, we hope it can help you effectively maintain the Extrusion Coating Lamination Machine, enabling it to operate stably for a long time and continuously empower production.